REPAIRING A CLINKER BUILT MOTORBOAT IN NEFYN

September 2020

There was always a boat in the back of our house in winter when I was growing up at 6 Church Street, Nefyn. My father Lawrence Owen was a fisherman and he owned a large motorboat and five rowing boats. When any boat was in need of structural repairs, Jimmy Trenholme the Church Street Garage owner and our next door neighbour, would bring it up from the beach and park it behind our house. I remember Jimmy bringing one boat on his truck and driving through the Bryn Mynach field (since made into a playing field) behind our house to get it there. The boat was slid over the earthen border wall past our outside toilet building and into the backyard.

We moved to live in 1 Glan y Pwll in 1952, a house incidentally with an inside toilet, as my mother Margaret Owen proudly relished and two years later my father got a job as a postman in the Nefyn Post Office. He could then only go fishing on a part time basis, so he decided to sell the large motorboat and get another one a little smaller. He kept the rowing boats so his three boys Michael, Brian, and Terry, as they came of age, could keep themselves occupied during their summer school holidays hiring the boats on Nefyn beach to English visitors.

My father got a bargain on a smaller, clinker built motorboat that had been damaged in a storm on Angelsey and afterwards found to be leaking. Again with help from his friend Jimmy, it was delivered to the back of our new house at Glan y Pwll. The Stuart Marine engine in the boat was nearly new and after stripping paint off the outside, a few planks in the hull were found to be damaged. Several ribs in the hull were also cracked and the boat required new decking in the bow and stern, together with new bottom boards.

These were repairs he felt he could easily fix himself.

My mother was not happy about the boat since she had to give up part of the vegetable garden she had already started in her new home. The back area in the house was small and now it was going to have a boat on it. The boat was acquired in the late summer of 1954 and my father agreed to make every effort to finish the repair work by early spring of the following year. He reasoned that after the summer was over and all the visitors had left, he would be able to finish his work, sorting and delivering the Nefyn mail by early afternoon and then he was free to work on the boat. The days did get shorter in winter but by working on weekends and with help from my elder brother Mike and myself, he was confident he could get it finished in time. He was very good at carpentry and especially how to fix those wooden clinker built boats. The boat versus garden became less of an issue later, after Siegfried Nierada opened the West End Garage across the road from Glan y Pwll and kindly allowed my father to park his boats in the grassy area behind the garage whenever they needed repairs.

To get going with the motorboat, my father first had to remove the engine and drive shaft from the boat to access all of the inner hull. He had to strip the paint off the boat to examine the ribs and planks which needed to be replaced. Then he had to ride his bicycle over Mynydd Nefyn to explain what he wanted and place an order with the carpenters at the lumber mill near the bridge in Pemprys on the Four Crosses road. We did not own a car. He made arrangements for the mill to let him know when the order was complete so he could come over with his bike again to pick them up. I remember going with him to get the wood. We tied the planks and ribs on to the handlebar and seat of our bikes and walked the bikes over the mountain all the way home. The copper nails and rivets required for the job were acquired from Wmffri at Shop Newydd in Nefyn. My father was then all set to start the job.

Replacing ribs and planks on a clinker built boat was a challenging job. It's an expertise rarely practiced anymore since modern boat hulls are now made of molded fiberglass. I am going to explain briefly how it was done in those days in the back garden of a house in a typical small coastal town like Nefyn on the Lleyn Peninsula. For Mike and myself, it was a fun time but there were tricky parts to the process as well. My father tackled the ribs first, carefully removing all the riveted nails that attached those damaged ribs to the hull and then the ribs themselves. Care was taken since removing too many adjacent ribs at one time could damage other planks or even distort the shape of the boat. The new ribs had to be steamed so they could be bent easily without breaking into the U-shaped hull and the procedure for doing this was to set up a makeshift rib steamer.

This was how a makeshift steamer was set up. My father made two holes on the opposite sides of a large empty oil drum, with the hole on one side approximately eight to ten inches higher than the hole on the other side. Then a cast iron pipe, blocked with concrete on one end and slightly longer than the length of a new rib, was inserted through the two holes with the blocked end extending just a few inches outside the lower hole. Support was provided for the open end of the pipe if required. The drum was then filled with coal or coke and lit up through a vent hole at the bottom. The upward angled pipe was half filled with water and brought to the boil. The ribs were inserted into the pipe and saturated in the steam and boiling water for about an hour. I would replenish the water a little bit at a time, while Mike and my father carefully bent the steamed ribs one at a time into the boat. They insured the rib made contact on all the planks and that it was centered correctly over the old nail holes, before clamping the rib at the boat edges. After all the ribs were in place, they were nailed at the boat edge and the excess wood cut off. The ribs were then left undisturbed to dry off completely. The planks that needed repair were also removed carefully. They were replaced with new planks extending the full length of the boat so no vertical plank joints were required. Horizontally along their lengths, the planks overlapped one another to provide the necessary water seal. That of course was the basic format of the wooden clinker design.

Now comes the not so fun part of the work of attaching all the parts together with the riveted copper nails. Perhaps I should explain that the old copper rivets for a boat were shaped like cones with their tops cut off and with the hole at the top fitting tightly over the appropriate sized copper nail. Those rivets are not common anymore. After the new ribs and planks were settled into the hull, holes were drilled through the ribs via the old holes in the planks. The ribs were then ready for riveting and they were worked on one at a time. Mike was somehow able to skip this part of the process and I was left alone to help my father. From the outside my father hammered all the nails through the planks and rib while I kept pressure on the inside, ensuring nothing moved. The process was repeated until all the ribs were nailed in place. Then the roles were reversed. My father, now on the inside, inserted a rivet over each nail, cut it to the appropriate length and clenched the nail end over the rivet with a special hammer. On the outside, I kept pressure on that nail head to prevent it from popping out even the slightest amount. The object was to pull all the parts together as tightly as possible. Problems often occurred due to one of us working on the wrong nail and we developed a careful procedure to prevent that from happening. It was difficult also to maintain effective pressure on the nail head since the tool could easily slip off during the hammering. If a slippage occurred and the nail popped up or the head bent, a new nail had to be inserted and the process repeated all over. My fingers ached and we took a short break after each nail and a longer break after each rib was completed. The process was repeated until all the new ribs were in the hull. The final part was to attach the new planks to the old planks in the areas between the ribs. This was done in a similar manner. It was hard work while lying on my back beneath the boat on a mat in the cold weather. After we were done, my father then attached the tapered ends of the new planks to the bow block and to the stern block of the boat.

He was meticulous about the work being done correctly and well. It would pay in the long run he would say. He finished the deck work and the bottom boards himself and then painted the boat together with the appropriate registered CO number. He reinserted the drive shaft and engine and the work was completed well ahead of schedule. He was pleased and my Mam was delighted she could get back to her gardening. After the motorboat was on the mooring in the Spring, it was checked thoroughly to ensure there were no leaks. The wood swelled due to the presence of water, pulling each join even tighter together. That smaller motorboat served my father well for over twenty years with no problems, a reflection on a job well done during those early winter days in the back garden at Glan y Pwll. All he had to do during that time was to periodically scrape and paint the boat's bottom with anti-fowling to deter seaweed growth which slows the boat's speed..

With the smaller motorboat, my father got rid of most of his lobster pots keeping only ten or so to provide for special customers. Likewise sightseeing trips to Bird Rock with visitors were also finished and he referred customers over to Dick Jones (Dicw) who had a large boat. He would go out to check his lobster pots and mackerel fishing only by himself or with family but he did take small parties out shark (tope) fishing when the weather was calm. He was starting to have problems with his back and the jarring of the boat in rougher seas were bothering him. His back became a major problem in the mid 1960's which required his hospitalization for nine months after a spinal fusion at the Orthopaedic Hospital in Gobowen, Shropshire.

My younger brother Terry went out with my father in the motorboat on some of those tope fishing trips and we have a photo record of the catch in one such trip in the early 1960's. A tope is a small shark which grows to a maximum length of four to five feet and they were the biggest sport fish around the Lleyn coast. They were abundant in summer everywhere in those days. The small sharks were a nuisance to fishermen since they often snapped off expensive mackerel fishing tackle. The tope were harmless though and rarely ventured into shallow waters. There were five people in the fishing trip group and the eldest gentleman had been out fishing with my father before. He wanted his grown children to experience the excitement of catching a shark. At the time, my father had an excess amount of mackerel so he had plenty for bait for the tope if required. He took the group straight out to sea from Nefyn Point to some land markers he preferred and dropped anchor. The group had three rods between them each with their own artificial lures which could be supplemented with mackerel if they desired. My father cut up some mackerel pieces and threw them over the sides as an enticement. They were fishing just off the sea bottom and it was not long before they started getting bites. Once a line had a definitive hit, all the other lines were pulled in to give the catcher free rein and to prevent the lines from getting tangled. They caught around twenty fish. Many were small tope, dogfish and spur dogs which were thrown back. They only kept the largest of the topes, a total of eight, with each person in the group having a chance to catch a big one. They returned to shore with four topes hanging off each side of the boat.

The elder gentleman was pleased that everyone had enjoyed themselves. Someone took their photograph with their catch on the Creigiau Bach breakwater afterwards. Due to over fishing, I don't believe it is legal to catch tope now in the UK and rightly so. My father was convinced years ago that tope and dogfish were used instead of cod in the fish and chip shops all over the country, thereby accelerating the rapid decrease in their population. According to him, the layered nature of the meat in the fish sold in the chip shop, made it more similar to small shark meat than cod. He still loved an occasional plate of fish and chips from the shop in Nefyn though.

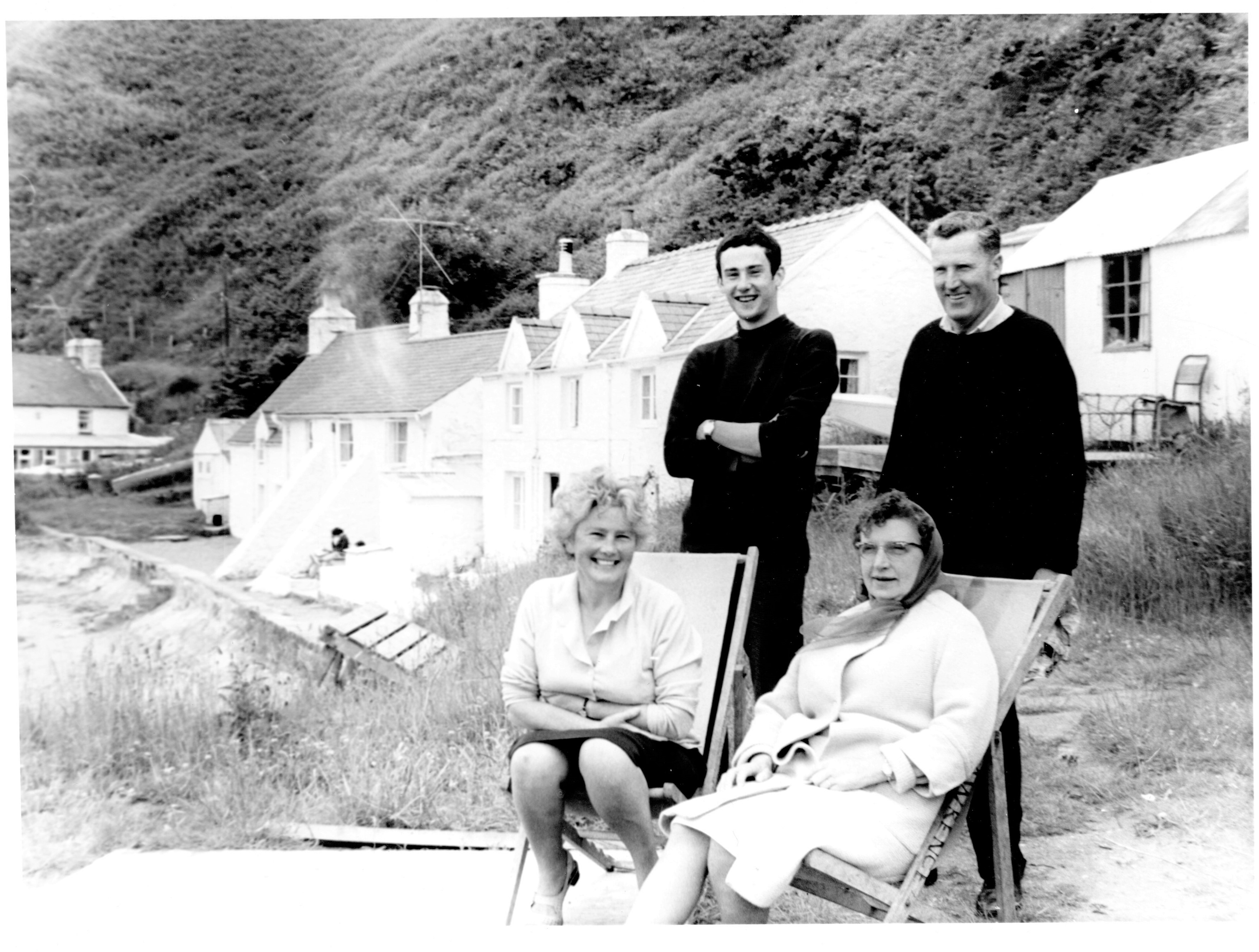

We did not have a camera in those early days so we do not have a stand alone photograph of the motorboat. But we do have photos showing the boat when it was being used. When Nancy and I visited Nefyn from America, we had several photos taken of us mackerel and lobster fishing in the motorboat. In the early 1960's, my parents also had a surprise visit from my father's elder sister Hilda. They had not seen each other since the 1930's when the family split up, with Hilda returning to England with the family while my father remained in Nefyn to marry my mother and start their own family. My father was pleased with her visit. Hilda's husband was a keen photographer and during their time in Nefyn, he enjoyed taking family photos and shots of my father fishing with Terry. Some photos taken by Hilda's husband of Terry and my father in the old motorboat, are shown below.

My mother catching a little late summer sun in 1954 in our back garden at 1 Glan y Pwll, Nefyn. She is sitting next to the motorboat being repaired by my father.

(Click photo to enlarge)

My brother Mike and his son Mark at 1 Glan y Pwll in the early 1970's with Siegfried Nierada's West End Garage across the road in the background.

(Click photo to enlarge)

A group photo on the Creigiau Bach breakwater showing the catch from a shark fishing trip in Nefyn in the early 1960's.

(Click photo to enlarge)

My wife Nancy, myself and my mother fishing in the old motorboat.

(Click photo to enlarge)

Lawrence pulling up a lobster pot in Bae Pistyll.

(Click photo to enlarge)

My father and Terry fishing for mackerel in Bae Pistyll.

(Click photo to enlarge)

Relaxing in the stern of the old motorboat.

(Click photo to enlarge)

My mother, father and Terry with Hilda, my father's sister, in front of his shed on Nefyn Beach.

(Click photo to enlarge)

Dr. Brian Owen

Emmaus, PA, USA

Top of Page